Advanced Analytics in AM Explorer

What is advanced analytics in AM?

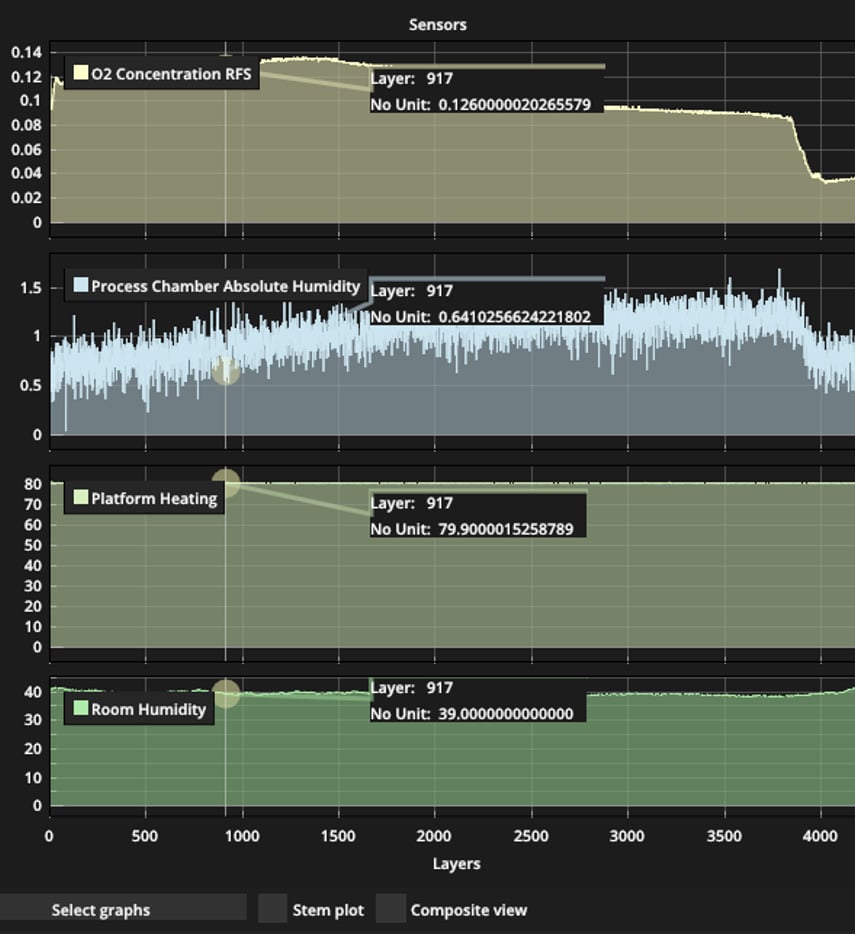

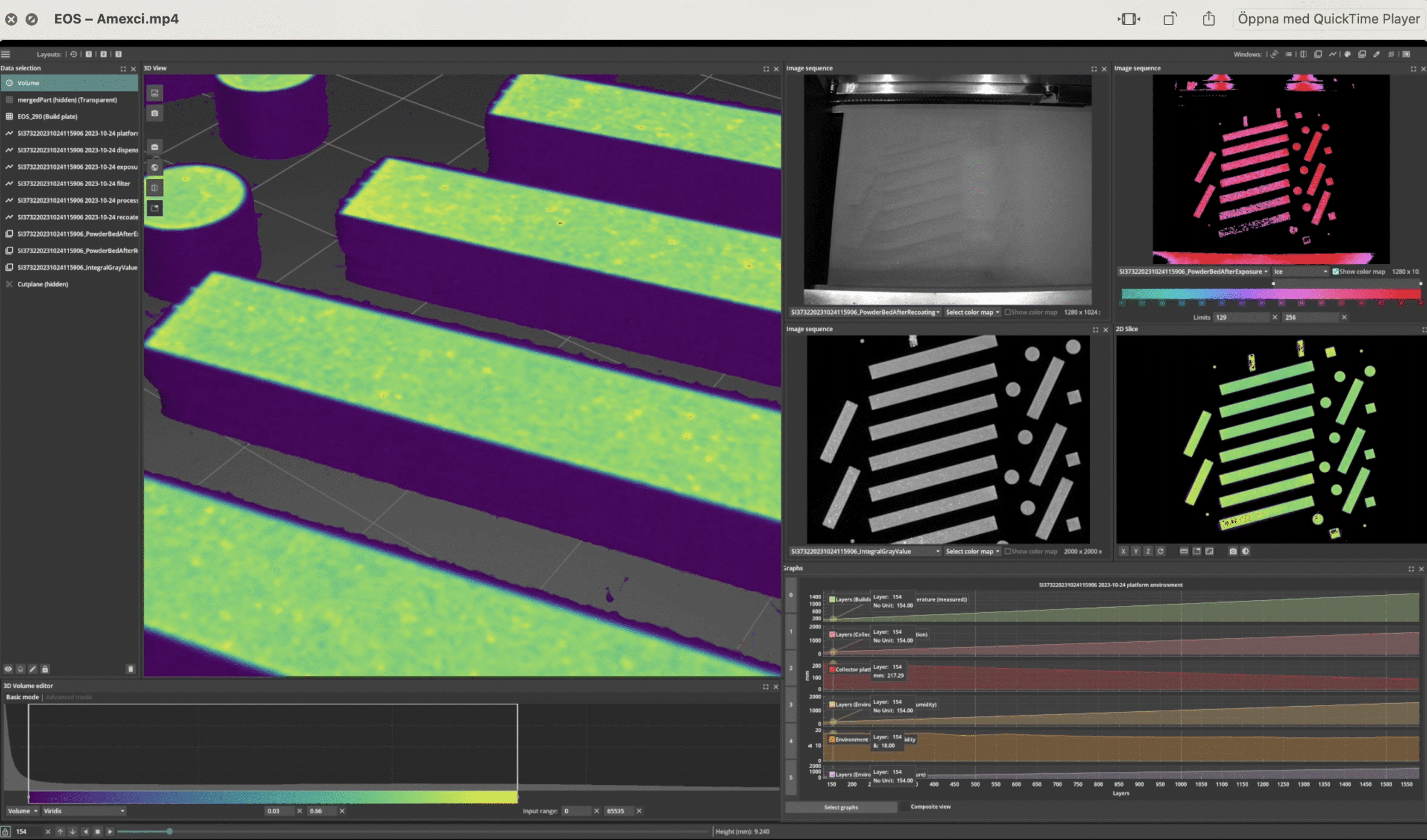

Advanced analytics refers to a set of techniques — including statistical modeling, image processing, and contextual filtering — used to analyze complex build data from additive manufacturing systems. It goes beyond simple metrics or thresholds to extract patterns, identify root causes, and optimize outcomes across the entire print process.

Why does it matter?

Metal AM processes generate enormous volumes of image and sensor data. Without advanced tools, teams face:

- Data overload with low-value or unclear indications

- High false positives from raw anomaly detection

- Limited insight into issue severity or root cause

With AM Explorer’s analytics engine, you can:

- Detect and classify build anomalies with higher precision

- Reduce noise and focus on meaningful patterns

- Build a scalable foundation for quality assurance

What advanced analytics capabilities does AM Explorer offer?

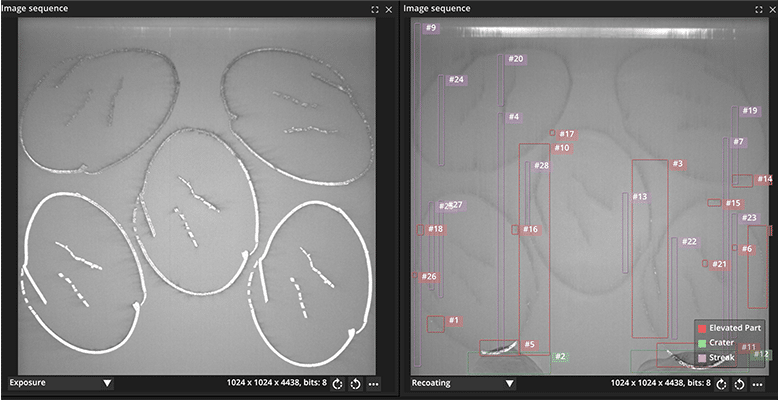

Object detection

- AI-driven models for defect detection on different printers and datasets

- Detection of error types like elevation, streaks, leakage, craters, and powder issues

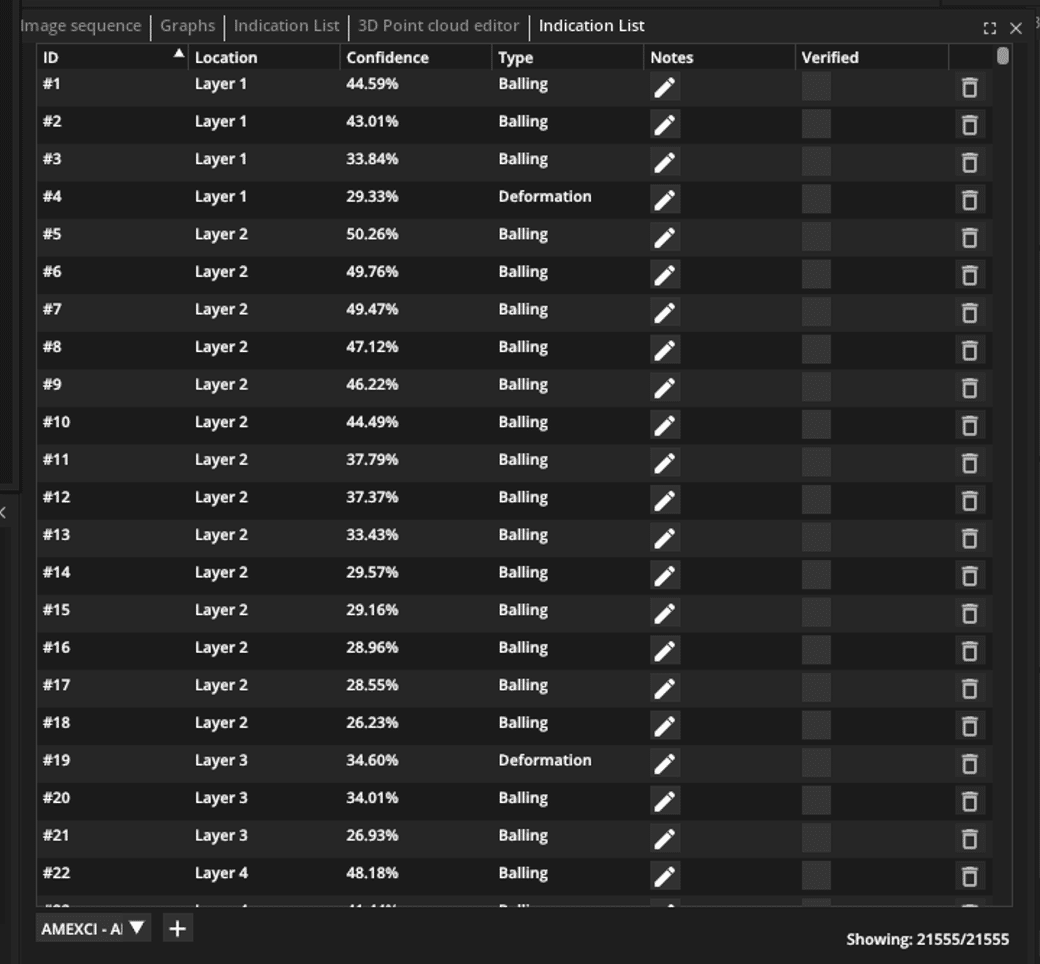

Post-detection filtering

- Multi-tiered contextual filtering to classify and reduce indications

- Filters based on context, frequency, and severity to surface

Indication characteristics

Detailed metrics for each anomaly like:

- Box area, streak length/magnitude

- On-part presence

- Largest affected surface area

- Layer-by-layer tracking

Visual filters for cleaner UI

- Aggregation of overlapping detections into unified boxes

- Adjustable thresholds for visual clarity and collaboration

Pixel-level segmentation & classification

- Advanced image analysis for identifying subtle build anomalies

How does it work in reality?

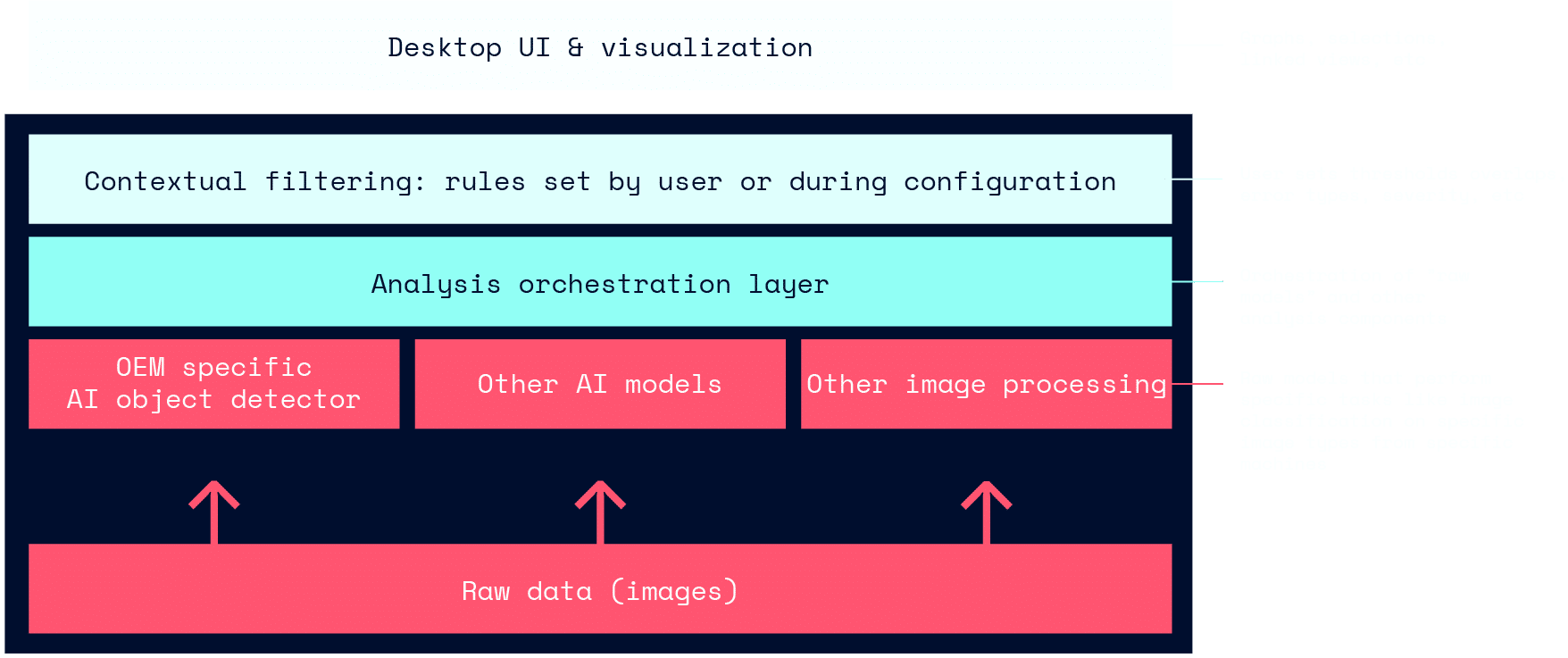

AM Explorer’s analytics engine works as a funnel:

- AI-based object detectors scan each layer image to identify potential issues.

- Contextual filters assess those results using geometric and temporal rules.

- Statistical processing and image segmentation add further depth, helping users classify, compare, and prioritize issues for action.

- All insights are visualized within the AM Explorer interface for instant review and sharing.

Analysis subsystem

Built for production use, our analytics engine is continuously refined using feedback from aerospace, defense, and energy customers. Read about how our customers use analytics for qualification.

Ready to reduce inspection time and qualify faster?

Partnering

Trusted by industry leaders in additive manufacturing

Deploy AM Explorer seamlessly across your entire additive manufacturing ecosystem—free from vendor lock-in, and designed to eliminate data and workflow bottlenecks. Gain full visibility and control over your production, regardless of machine type or data source.

Interspectral is a fast-growing tech company based in Norrköping, Sweden, specializing in 3D digitization, 3D visualization, and advanced data fusion. We serve a global market with customers in over 20 countries.