AM Explorer QUALIFY – qualify with confidence

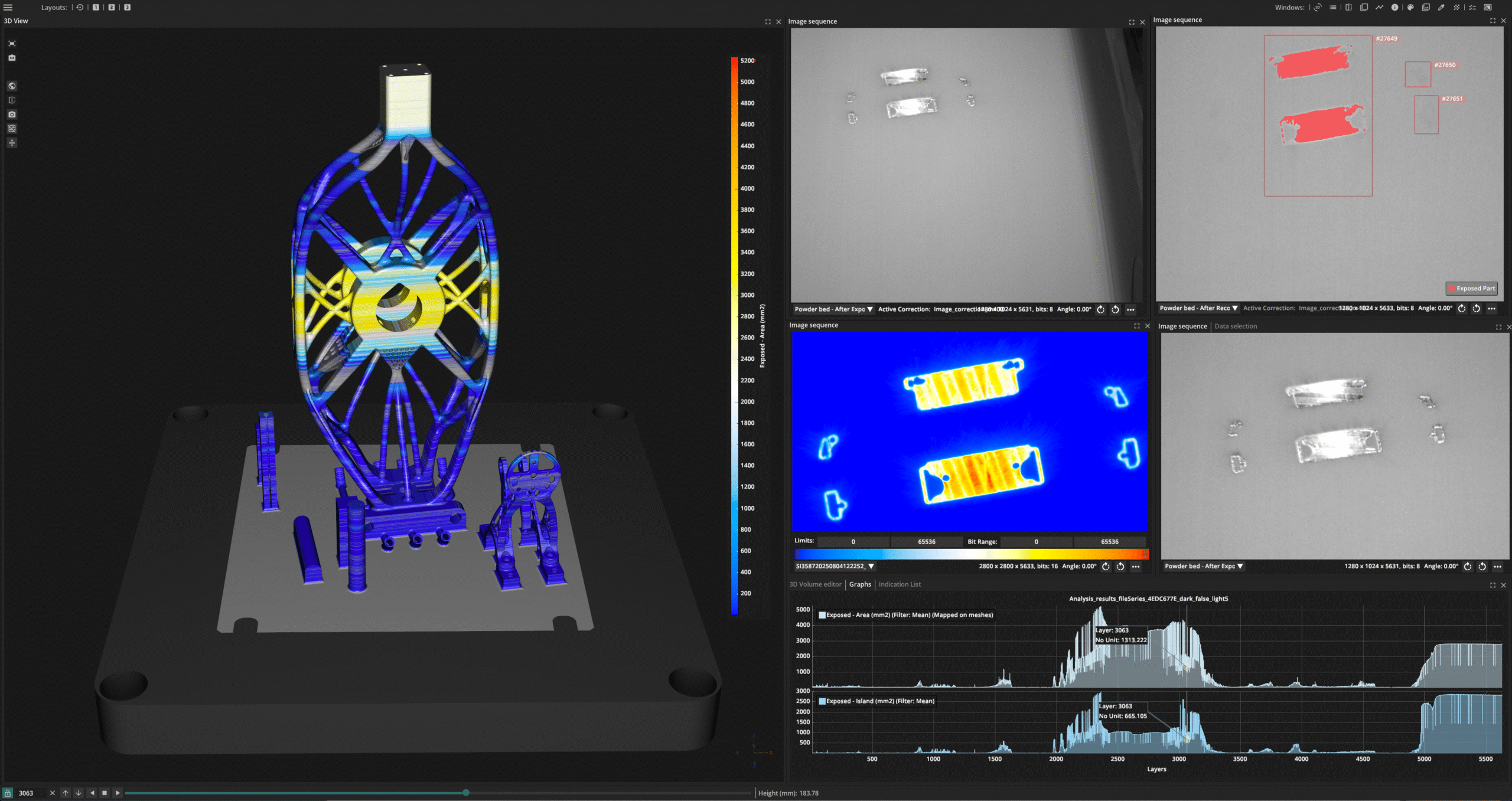

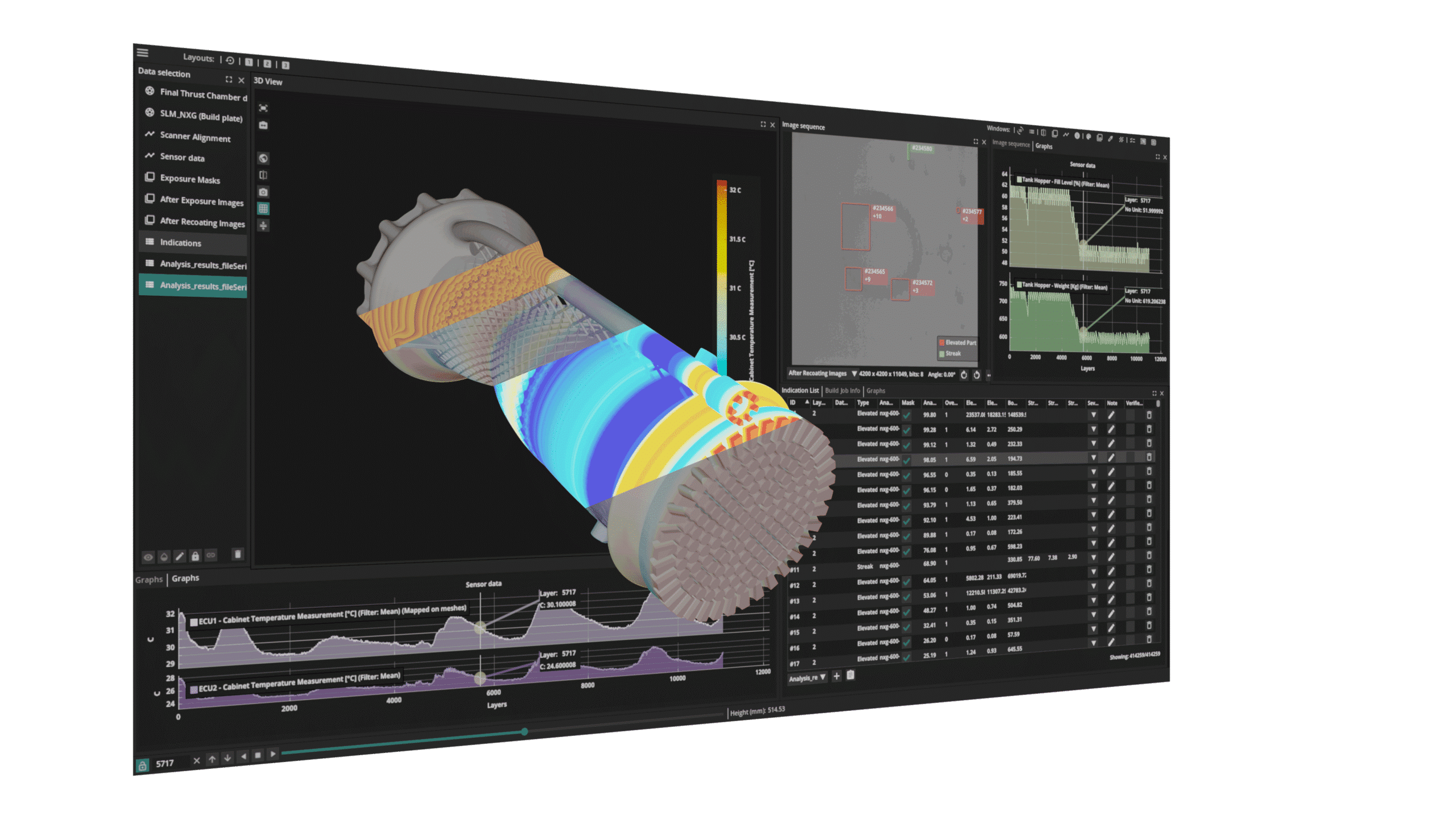

AM Explorer QUALIFY provides a flexible, data-driven platform to optimize manufacturing parameters, support experimentation for innovation, and ensure repeatable performance. With advanced visualization and analytics, it enables faster, more accurate build validation, root-cause analysis, and confident part qualification.

Use cases

Key benefits

Product highlights

Discover the AM Explorer

product suite

For detecting and identifying anomalies.

For in-situ monitoring.

Built for scale.

Partnering

Trusted by industry leaders in additive manufacturing

Deploy AM Explorer seamlessly across your entire additive manufacturing ecosystem — free from vendor lock-in, and designed to eliminate data and workflow bottlenecks. Gain full visibility and control over your production, regardless of machine type or data source.